Busting the myths around ERP system

Business finance and accounting processes are managed through ERP accounting systems. They offer a comprehensive method for tracking and reporting a company’s financial data and transactions; the software is available as either Cloud ERP or ERP on Cloud depending on whether it is deployed on cloud servers.

An ERP in accounting enables you to precisely set up the system so that all transactions are correctly accounted for and automatically reported. Experience shows that many businesses underestimate the requirements for a successful conclusion, beginning with the ERP choice and going all the way to the implementation itself.

1. For small businesses, ERP solutions are too expensive and complex

It is not the case anymore since ERP since the restriction of small companies has primarily reduced because of the recent developments. ERP no longer need to spend money on pricey hardware, IT skills, and network infrastructure.

For the workplace to function well, even small firms, especially those that want to expand, require an efficient accounting system. Also, integrations with external systems are a lot easier, more affordable, and more customizable today than they were before. Thus, a program that can expand along with the business is needed.

2. The most significant factor is price

Many people think an ERP accounting system is pricey, especially first-time ERP customers for whom cost was the most important element. Yet with a second customer, they understood the importance of the degree of contact and support with the seller.

By investing in ERP software that is less error-prone and frees up resources for more strategic activities, you are not merely purchasing an a software program; instead, you are reducing the need for rework.

3. An ERP must be implemented all at once.

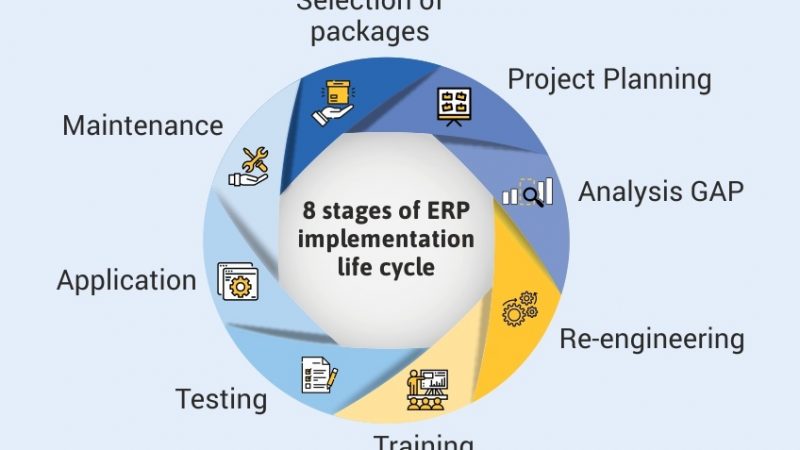

One of the most widespread misconceptions about implementing the financial ERP system is that it should be done all at once since it may take weeks or even months to integrate with the company’s current technological environment. But that’s not necessary; an ERP can be introduced gradually so that you can make optimum use of all the resources and operations. And it is advised to tackle the challenging aspects first.

4. It’s difficult to comprehend ERP system software.

ERP system software is difficult to comprehend.

Each new system is expected to take extra time and extensive training sessions to learn, comprehend, and adapt to.

One of the main causes of unsuccessful or underutilized ERP installations is that there was inadequate funding for training, which caused users to struggle with the brand-new system and not benefit immensely from it.

Many businesses don’t complete the reviewing process and then wonder why their ERP appears to be a carbon copy of what they were doing before. Moreover, businesses frequently underestimate the time required to adopt an ERP.

They are unaware of the intricacy of their operations or the large time commitment required by individuals who already work a full-time day job.

The route of simple learning and adaptation to the new system that enables individual growth for the users will undoubtedly be paved by appropriate training, user-friendly eLearning courses, timely support, and efficient maintenance services.

5. ERPs lack user-friendliness.

In the past, ERPs were sluggish, cumbersome, and challenging to use. The necessary training was time-consuming and difficult. Nonetheless, thanks to contemporary technology, user-friendly interfaces have greatly facilitated the implementation of ERP.

User acceptance will rise as a result of the ERP solution’s familiarity and usability, which SMB solutions provide. It’s crucial to evaluate ERP solutions and pick the one that best suits your needs in light of your company’s needs, market trends, functionality, and features.

Several ERPs available today are browser-based, allowing for remote access. It has become simpler thanks to social media and friendly mobile apps.

One of the most important purchases your business will ever make is an ERP system. As it is a crucial business system that will support your company for many years to come, you want to make sure that its deployment goes perfectly.

The use of ERPs may enhance human processes at work by reducing mistakes, saving time, and reducing costs. Nonetheless, the human element of such procedures is not eliminated.

To say that the transactions handled are numerous, intricate, and repetitious is not an exaggeration. So, acquiring an excellent ERP accounting system from SMB solutions is essential.

SMB solutions is a company that offers customized services and enterprise solutions developed with input from the industry to help clients in important sectors succeed.

Customers have access to solutions, procedures, and tools through our ERP system to help manage data for essential business insights and well-informed decisions.