How to Make your Manufacturing Operations Smooth with ERP System?

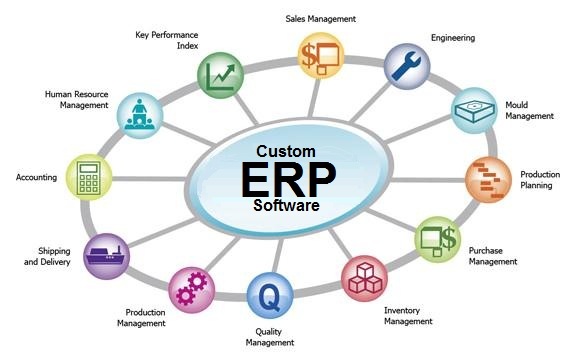

In the manufacturing sector where there is strict and high competition based on quality and delivery time, it is very important to have efficient operations to meet the customer needs, control the resources and make profits. But managing inventory, production, quality, and supply chain management can cause a number of problems. This is where an Enterprise Resource Planning (ERP) system becomes highly valuable.

All the main business activities can be combined into one unified system, which helps manufacturers reduce costs and guarantee a high level of quality as well as making the process smooth and sustainable.

Let’s discuss in detail how ERP in manufacturing sector is used to smoothen the operational processes:

What is ERP in the Manufacturing Industry?

ERP (Enterprise Resource Planning) is a software application that aims at the effective management of business operations such as inventory, production, finance and human resource. In manufacturing, ERP systems facilitate the automation of business processes, management of resources, and decision making.

Example:

A furniture manufacturer uses an ERP system to control the procurement of raw materials, to integrate production planning and control and to monitor customer orders. It also generates automatic notifications when the stock level goes low, orders raw materials and guarantees delivery to the customers. This integration reduces delays, cuts wastage and generally enhances the operations of the entire manufacturing process thus making the process smoother and more reliable.

Enhancing Manufacturing Operations with ERP Systems

A good ERP system is the foundation on which the manufacturing operations are built and delivers value by avoiding the wastes and enhancing communication. Here are the key ways it drives smoother operations:

Streamlined Processes:

ERP systems link several business activities such as order management, production scheduling and materials requirement planning. The integration of these systems reduces gaps and makes work easier by allowing the flow of information from one department to another.

Real-Time Data Insights:

Another major advantage of ERP systems can be attributed to the fact that they offer real-time information and analysis. This makes it possible for manufacturing enterprises to be in a position to make right decisions at the right time depending on the current information on stocks, production status among other factors.

Automated Workflows:

ERP systems replace most of the manual tasks and activities within an organization. This automation also ensures that there are few mistakes made in the process while increasing the general productivity of the manufacturing processes.

Improved Resource Utilization:

Through ERP, organizations are able to manage the consumption of resources for instance materials, equipment and human resources. This optimization results in improved efficiency, less wastage and therefore; reduced cost.

Enhanced Collaboration:

ERP is effective in improving communication and integration between different departments. All teams can use the same actual-time data, which makes the overall structure of the manufacturing processes more integrated.

Accurate Inventory Management:

Inventory status is well managed by ERP systems to ensure that the right information about the stock is produced and is up to date. This aids in avoiding over stocking or stocking out situations, reducing holding cost, and also ensuring that the production rate is inline with the demand rate.

Demand Forecasting:

Using history and analysis, ERP plays a role in demand planning by providing data to the forecasting process. This capability helps manufacturers to forecast the market direction, and produce accordingly to meet the customers’ needs.

Quality Control:

Quality assurance and control are some of the modules that are normally incorporated into ERP systems. These modules assist in ensuring product quality is checked and maintained at every stage of production hence minimizing defects and customer complaints.

Cost Tracking and Analysis:

ERP systems can also track and analyze costs related to manufacturing processes in detail. This visibility into costs is useful in the assessment of areas that require optimization, control of expenses and ensuring that a business remains profitable.

Regulatory Compliance:

A majority of ERP systems have tools and functionalities that help in compliance with the regulations. This is especially important in sectors where the company has to follow certain standards and norms to avoid running afoul of the law.

The Bottom Line

The adoption of an ERP system is a revolution for manufacturing businesses as it makes operations efficient, effective and affordable. ERP system empowers the organization’s key operations, such as inventory control, production planning, and quality assurance, by coordinating them effectively across the departmental silos. It also has the added advantage of real-time information and processing so that decisions can be made more quickly and resources used more efficiently.

When adopting this system, an organization does not have to worry about an ERP system’s ability to expand as the business expands since it meets the growing needs and complexities of the market while still operating within the legal and customer requirements.

Working with us offers unique, customized manufacturing ERP solutions that eliminate implementation problems and offer training and further assistance to enhance your system’s performance. Whether it’s about managing stocks or setting up production plans, we assist companies like yours in getting operations right for sustainable development.

Call SMB Solution today, and let us build the right ERP solution for you!