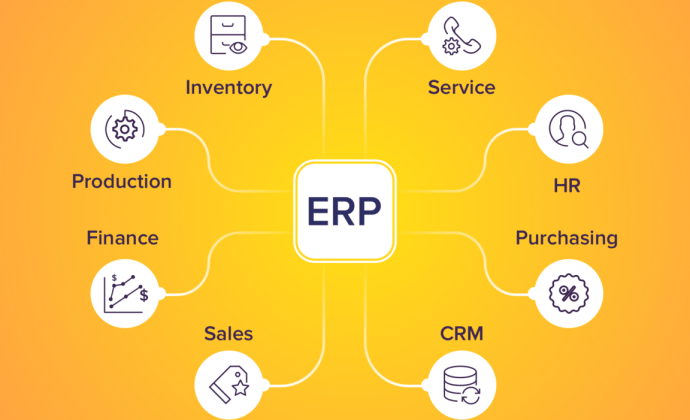

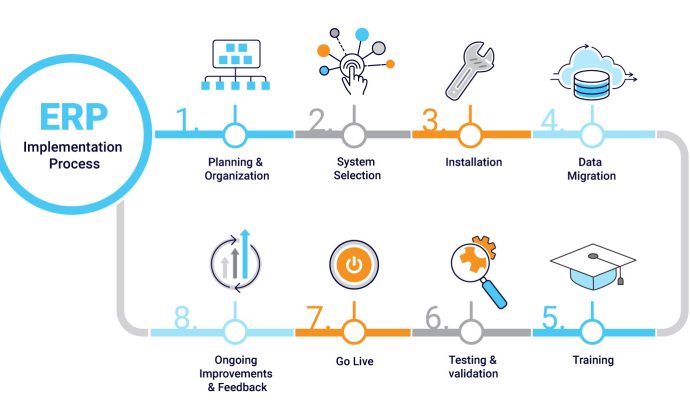

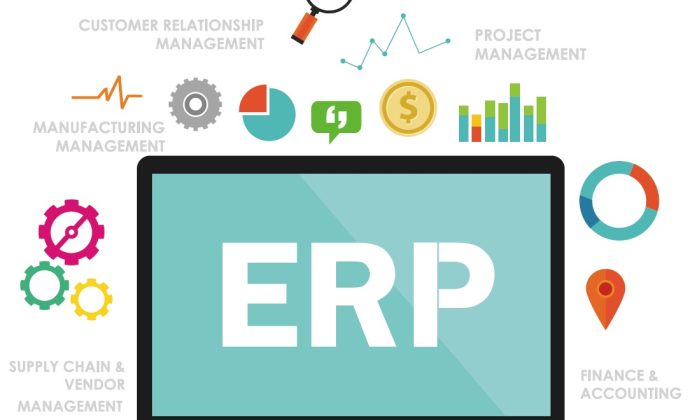

The Enterprise Resource Planning (ERP) system or software is a computer software program used by businesses to manage business operations. It accomplishes this by monitoring the company’s inventory, production, clients, and personnel. Additionally, it offers information about the business to aid in decision-making. One of the most audacious things a company can do to computerize its operations is to install an ERP system. Even while most company professionals have heard of ERP, they might not be aware of the benefits it can provide for their employees. In 2023, ERP systems will be able to assist businesses in being more productive, efficient, and capable of making wiser judgments. What exactly is an ERP system and ERP software? An ERP system’s main objective is to streamline and automate business activities in order to increase productivity and profitability. Modern ERP systems give insight, visibility, and efficiency across every business unit by utilizing cutting-edge technology like machine learning and artificial intelligence. What is an ERP System? ERP is fundamentally different from other forms of business software, such as simple accounting, scheduling, or task management, which are used by a single user or a small group and don’t directly interact with other programs. they provide firms with information about things like inventory levels, production outputs, and consumer demand, which helps them make better judgments. What is ERP Software? Enterprise resource planning software, sometimes known as ERP software, is a class of company management software that aids in managing an organization’s resources, such as finances, customer information, production processes, and supply chains. This reduces instances of repetition, mistakes, and rework and helps your company save a lot of time. A real-time picture of the data is provided by ERP software, together with simple reporting and analysis that facilitate wise choice-making. ERP software connects with all essential business processes to manage and synchronize activities throughout the whole company. Generally speaking, ERP systems automate and record many manual activities, which reduces error-proneness and increases efficiency. Even though ERP is not a new concept, it appears that ERP systems are advancing quickly. They are more capable than ever before and enable cutting-edge features like Customer Relationship Management (CRM) and Enterprise Resource Planning (ERP), in addition to simple inventory management. ERP systems can readily adapt to changes like increased production, expanded inventories, or the addition of additional users, services, or functionalities. In other words, it aids in the digital transformation of businesses. The ability of ERP systems to follow industry laws and changes in compliance is one of its most potent benefits. This makes it possible for firms to remain on top of regulations, pertinent legislation, and standards. So, ARE YOU ERP READY? It’s time to set up an ERP system in your company if you don’t know the answers to crucial business-related issues like revenue and the quantity of returned goods. The majority of best-of-breed ERP solutions today offer an extensive ecosystem of supporting apps for your particular requirements, and these integrations are tailored to your sector. Too many unrelated programs may be at blame if it’s taking longer to manage fundamental tasks like closing the books. Your finances, sales, operations, and human resources may all be managed in one location using ERP. It’s a dangerous sign for your company if you’re passing up fresh prospects. A new set of ERP skills prioritizes broad business expertise and collaboration to write the next chapter in the long partnership between ERP and business which is also required because of digital transformation. An ERP installation partner cannot be classified into a single, universal category. The greatest strategy, according to SMB Solutions, for effectively integrating an ERP system with a partner is to pick the appropriate expertise for your sector, your system, and your top priorities. We make sure to comprehend your business strategy and get along well with your internal project team. We will work with you to automate your processes so that you may have a clearer picture of your business, eliminate mistakes by doing away with manual procedures, and provide a single point of access for information.

A Brief Guide About ERP System And Software In 2023